Woven Wire Series

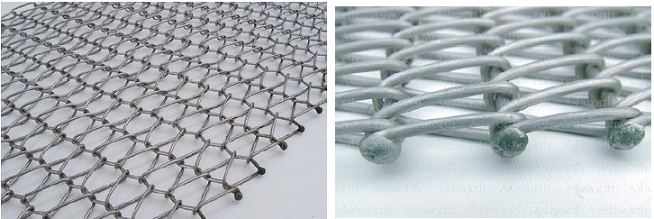

WG Woven Wire

Ashworth "WG" woven wire conveyor belts are among the most versatile and widely used metal conveyor belts available, thanks to their characteristics of true travel, good flexibility, excellent strength-to-weight ratio, flat surface and minimal maintenance requirements. These quality belts are straight running, friction driven and have welded edges. WG belts employed in food processing applications are constructed of FDA-approved materials and can be found in baking, cooling, frying, pasteurizing and drying machinery.

WG woven wire belts can also be produced from a wide variety of stainless, carbon and galvanized steels and high temperature alloys for many different industrial applications. Examples include belts utilized in glass and ceramic processing ovens, small component manufacturing processes, packaging and general conveying, and product transfer and packaging applications.

Product Applications

-

Tunnel Oven Belts

-

Industrial Product Processing, Transfer and Packaging Belts

-

Annealing Oven Conveyor Belts

-

Drying and Cooling Conveyor Belts

-

Pasteurizer Belts

______________________________________

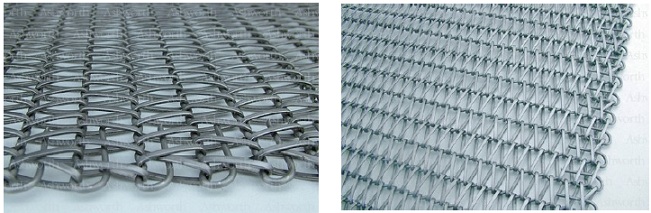

WGI Woven Wire

Ashworth "WGI" woven wire conveyor belts are the closed mesh version of our renowned WG belts. Like our WG belts, WGI belts are of balanced weave construction, and are manufactured with alternating right- and left-hand spirals joined by crimped connectors. They also have welded edges, are straight running, friction driven by terminal drums and can be manufactured with spirals produced from either round or flattened wire. But in contrast to Ashworth WG belts, our WGI series belts have many more connector rods and spirals per length of belt. This construction provides a closed mesh surface that is extremely strong, flat and supportive.

Available in widths of up to 6000 mm, and in a wide variety of materials, WGI belts are popular for use in all types of ovens, including baking tunnels for food products or in high temperature industrial ovens of differing types. And, due to their extremely closed mesh, WGI belts are also popular for processing and conveyance of many types of small parts. WGI belts are also extraordinarily strong, so they can withstand the weight of heavy loads and high tensions.

Product Applications

-

Tunnel Oven Belts

-

Annealing Oven Conveyor Belts

-

Glass and Ceramics Oven Belts

-

Metal Parts Conditioning and Annealing Belts

-

Small Parts Processing Belts

______________________________________

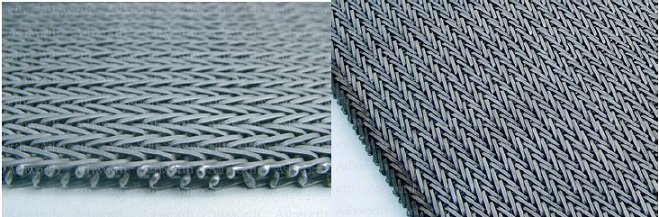

WU Woven Wire

Ashworth has developed and refined our line of "WU" woven wire belts, which are specifically designed for drying of solid wood and wood veneers. Ashworth WU belts are manufactured using specially formulated stainless steel wire, so they are non-marking and gently convey the most sensitive wood products, including those that are bright, blank or lightly grained.

Ashworth WU belts are made with U-hooked clinched edges, which contain no welds. This enables WU belts to remain flexible under extreme operating conditions, and ensure a flat, smooth and level belt surface. Further, WU belts are manufactured with flattened wire spirals (round wire spirals are available upon request). The combination of weld-free edges and flattened spirals provides the belt with the benefits of minimal wear and optimal contact between the belt and the products' surface.

As a result, the wood processor receives a quality dried wood product without markings attributed to the conveyor belt. Thus, WU belts generate minimal scrap, reducing processing costs. And because WU belts are extremely flexible, they last longer-further contributing to the bottom line.

Product Applications

-

Wood Veneer Drying Oven Belts

-

General Conveyance and Processing Applications

-

Solid Wood Drying Oven Belts

_____________________________________________________________________________________________

Click here to download Ashworth Conveyor Belt Product Catalog

For more details, please visit ASHWORTH.com

For enquires, please email to jasonling@unibelt.com.sg